Light-weight, low emission nitrogen vaporizers for high-volume oil-field

and other industrial nitrogen requirements.

|

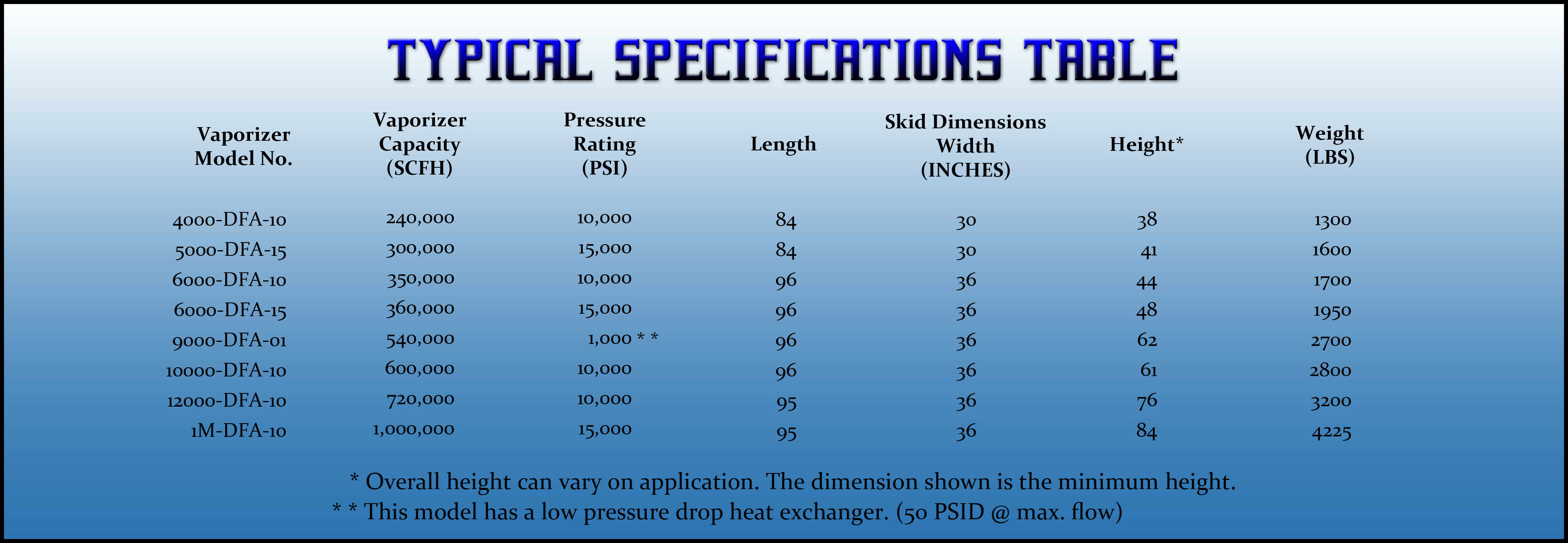

DK Aerospace & Industrial direct-fired cryogenic vaporizers are the end products of years of creative engineering and production skill. They represent a complete line of reliable, rugged, light-weight, low-emission units capable of delivering from 4,000 to 15,000 SCFM of gaseous nitrogen, with superior field-proven performance in converting liquid nitrogen to gas for industrial and oil field operations. These units use a patented high-efficiency combustion system combined with a compact stainless steel heat exchanger and simple reliable controls. They are packaged with portability in mind. Even the largest units have overall length of only eight feet to facilitate mounting on the user's truck or trailer. Simple Controls DK vaporizers have simple control systems especially designed and fabricated to withstand the rigors of the drilling environment and the shock and vibration of transportation. Two basic types of controls are available: manual controls, and completely automatic controls with manual override provisions. After a simple start-up procedure, the units with automatic controls maintain a constant (operator selected) burner discharge temperature (nominally 1200F) over the full range of air flow rates. Automatic safety shutdown features are provided for ignition failure, flameout, or temperatures that fall outside of set limits. The manual backup system enables the operator to take over operation from the automatic control system if necessary. The manual control system is the ultimate in simplicity, reliability, and ease of maintenance. Three toggle switches and a needle valve control all burner functions including ignition, pilot operation, and switchover to main burner. Clean Burner The heat required to vaporize the liquid nitrogen is supplied by a patented high efficiency, light-weight, continuously piloted burner -- a product of DK Manufacturing's work in low-emission combustion. These clean-burning, efficient units are extremely compact. They provide more than 1.5 million BTU/hr/ft of burner volume. |

The continuous piloting feature of these unique combustion systems is

particularly important for oilfield applications. The burner can be started

and placed on standby at less than 4 gallons per hour fuel consumption until

full scale pumping is required. Then, with the flick of a switch, they can

change over instantly to maximum flow main burner operation. The operator can

adjust the heat output through a twenty-to-one turn down range with no

problems in either burner operation or emissions.

All combustion and flame is confined to the inlet portion of the combustion chamber, resulting in clean, uniform flow of combustion products through the heat exchanger, free from soot and flame. Because the burner discharge temperature is controllable by the operator from 500F to 1200F, the gas flow is never hot enough to damage the stainless steel heat exchanger tubes. Heat exchanger integrity does not require a continuous supply of liquid nitrogen to the unit. Heat Exchanger Solidly constructed from stainless steel tubing with welded stainless fins, the compact heat exchanger is capable of vaporizing liquid nitrogen at pressures up to 15,000 psi. Although the nominal nitrogen discharge temperature is 70F, discharge temperatures up to 800F can be delivered at reduced flow rates from all units. Special low-pressure heat exchangers are available for 500 psi working pressure, which feature a low 50 psi drop across the heat exchanger. All DK heat exchangers are pressure tested to 1.5 times operating pressures, and are subjected to complete performance tests to verify their heat transfer capabilities. |

If you are interested in purchasing this product, please contact us.